|

|

| MOQ: | 1000 |

| Price: | Negotiable |

| Standard Packaging: | PE inside , Carton Outside |

| Delivery Period: | 5-8 work days |

| Payment Method: | TT |

| Supply Capacity: | On demand production |

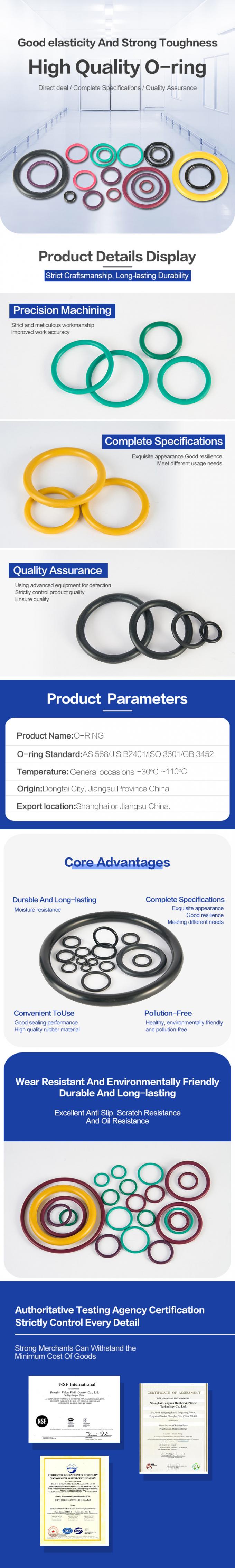

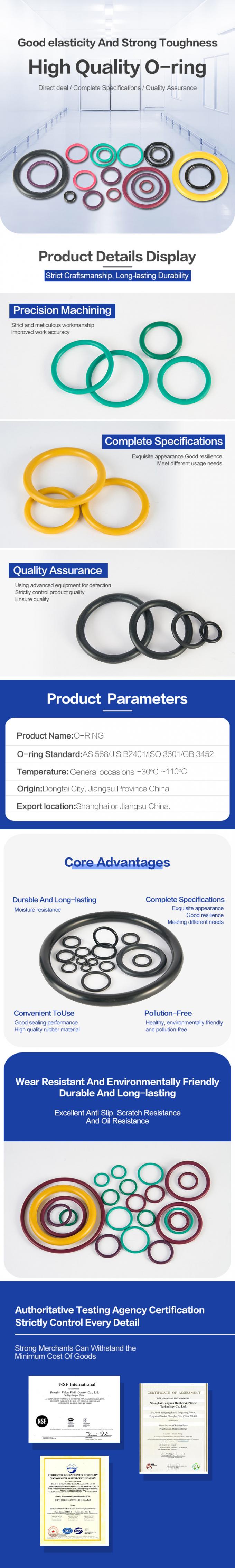

But the benefits of our NBR O Rings don't stop there. With a temperature range of -25°C to +100°C and good chemical resistance, these O Rings can stand up to a wide range of environments and substances. Whether you're working with hydraulic oils, fuels, or other fluids, you can trust these O Rings to maintain their integrity and keep your machinery running smoothly.

So why choose Nitrile Butadiene Rubber (NBR) for your O Rings? This type of rubber is known for its excellent resistance to oils, fuels, and other petroleum-based substances, making it ideal for use in hydraulic systems. It also offers good resistance to heat and abrasion, ensuring that your O Rings will last longer and require less maintenance over time. And with our high-quality manufacturing processes and attention to detail, you can be confident that our NBR O Rings will meet your exact specifications and exceed your expectations.

The FOLON.A Factory NBR O Rings are widely used in various applications, including hydraulic and pneumatic systems, automotive, aerospace, chemical processing, food and beverage, and water treatment industries. Their oil resistance, wear resistance, and ability to withstand high pressure make them ideal for use in sealing applications where resistance to oil, fuels, and other chemicals is required.

The NBR O Rings are suitable for use in a range of temperatures and environments, making them a versatile choice for sealing applications. They are available in different sizes and shapes, with a hardness of 70-90 Shore A and a round shape. The high-quality NBR material ensures that they are durable and long-lasting, making them an ideal choice for use in demanding applications.

With their on-demand production supply ability, the FOLON.A Factory NBR O Rings are readily available to meet the needs of customers. They are a reliable and cost-effective solution for sealing applications that require oil resistance, wear resistance, and high-pressure resistance.

Our NBR O Rings are made from high-quality nitrile rubber material that is resistant to oil, fuel, and other chemicals. We offer a wide range of sizes and shapes to meet your specific needs. Our expert technical support team is available to answer any questions you may have about our products and can provide guidance on installation and maintenance. Additionally, our comprehensive services include custom sizing, material selection, and prototyping to ensure the perfect fit for your application. Contact us today to learn more about our NBR O Rings and how we can assist you.

Product: NBR O Rings

Packaging: The NBR O Rings are packaged in a sealed plastic bag to ensure they are protected from dust and moisture during shipping and storage. The bags are labeled with the product name, size, and quantity for easy identification.

Shipping: The NBR O Rings are shipped in a sturdy cardboard box to prevent damage during transit. The box is labeled with the product name, size, and quantity, as well as the recipient's address and any other necessary shipping information.

Q1: What is the brand name of the NBR O Rings?

A1: The brand name of our NBR O Rings is FOLON.A.

Q2: What is the minimum order quantity for the NBR O Rings?

A2: The minimum order quantity for our NBR O Rings is 1000.

Q3: What is the certification of the NBR O Rings?

A3: Our NBR O Rings have TS16949, IATF, NSF, ISO9001, PPAP, ROHS, FDA, LFGB certifications.

Q4: What is the delivery time for the NBR O Rings?

A4: The delivery time for our NBR O Rings is 5-8 work days.

Q5: What are the packaging details for the NBR O Rings?

A5: Our NBR O Rings are packaged with PE inside and Carton Outside.

Price: Negotiable

Supply Ability: On demand production

Payment Terms: TT

Model Number: Factory

Standard: AS568, BS1516, JISB2401, ISO3601, DIN3771, DIN3869

Place of Origin: China

|

|

| MOQ: | 1000 |

| Price: | Negotiable |

| Standard Packaging: | PE inside , Carton Outside |

| Delivery Period: | 5-8 work days |

| Payment Method: | TT |

| Supply Capacity: | On demand production |

But the benefits of our NBR O Rings don't stop there. With a temperature range of -25°C to +100°C and good chemical resistance, these O Rings can stand up to a wide range of environments and substances. Whether you're working with hydraulic oils, fuels, or other fluids, you can trust these O Rings to maintain their integrity and keep your machinery running smoothly.

So why choose Nitrile Butadiene Rubber (NBR) for your O Rings? This type of rubber is known for its excellent resistance to oils, fuels, and other petroleum-based substances, making it ideal for use in hydraulic systems. It also offers good resistance to heat and abrasion, ensuring that your O Rings will last longer and require less maintenance over time. And with our high-quality manufacturing processes and attention to detail, you can be confident that our NBR O Rings will meet your exact specifications and exceed your expectations.

The FOLON.A Factory NBR O Rings are widely used in various applications, including hydraulic and pneumatic systems, automotive, aerospace, chemical processing, food and beverage, and water treatment industries. Their oil resistance, wear resistance, and ability to withstand high pressure make them ideal for use in sealing applications where resistance to oil, fuels, and other chemicals is required.

The NBR O Rings are suitable for use in a range of temperatures and environments, making them a versatile choice for sealing applications. They are available in different sizes and shapes, with a hardness of 70-90 Shore A and a round shape. The high-quality NBR material ensures that they are durable and long-lasting, making them an ideal choice for use in demanding applications.

With their on-demand production supply ability, the FOLON.A Factory NBR O Rings are readily available to meet the needs of customers. They are a reliable and cost-effective solution for sealing applications that require oil resistance, wear resistance, and high-pressure resistance.

Our NBR O Rings are made from high-quality nitrile rubber material that is resistant to oil, fuel, and other chemicals. We offer a wide range of sizes and shapes to meet your specific needs. Our expert technical support team is available to answer any questions you may have about our products and can provide guidance on installation and maintenance. Additionally, our comprehensive services include custom sizing, material selection, and prototyping to ensure the perfect fit for your application. Contact us today to learn more about our NBR O Rings and how we can assist you.

Product: NBR O Rings

Packaging: The NBR O Rings are packaged in a sealed plastic bag to ensure they are protected from dust and moisture during shipping and storage. The bags are labeled with the product name, size, and quantity for easy identification.

Shipping: The NBR O Rings are shipped in a sturdy cardboard box to prevent damage during transit. The box is labeled with the product name, size, and quantity, as well as the recipient's address and any other necessary shipping information.

Q1: What is the brand name of the NBR O Rings?

A1: The brand name of our NBR O Rings is FOLON.A.

Q2: What is the minimum order quantity for the NBR O Rings?

A2: The minimum order quantity for our NBR O Rings is 1000.

Q3: What is the certification of the NBR O Rings?

A3: Our NBR O Rings have TS16949, IATF, NSF, ISO9001, PPAP, ROHS, FDA, LFGB certifications.

Q4: What is the delivery time for the NBR O Rings?

A4: The delivery time for our NBR O Rings is 5-8 work days.

Q5: What are the packaging details for the NBR O Rings?

A5: Our NBR O Rings are packaged with PE inside and Carton Outside.

Price: Negotiable

Supply Ability: On demand production

Payment Terms: TT

Model Number: Factory

Standard: AS568, BS1516, JISB2401, ISO3601, DIN3771, DIN3869

Place of Origin: China